thyssenkrupp expands portfolio of smart stockyard and smart port solutions

Published by Lydia Woellwarth,

Editor

Dry Bulk,

thyssenkrupp Industrial Solutions is strengthening its portfolio of digitalised solutions for bulk materials handling. Identifying the challenges faced by customers seeking better operating performance, less wear on equipment and more safety, the company has developed solutions that integrate software and hardware, allowing insights through data analysis to improve the operation and maintenance of machines and systems.

“4.0 solutions can greatly contribute to the increase of operational efficiency in the mining sector. That is why we at thyssenkrupp Mining Technologies have organised our automation and digitalisation expertise in our competence centres in India and Germany”, says Jan Lueder, CEO of thyssenkrupp Mining Technologies. “To specifically address today’s bulk materials handling challenges we have developed smart stockyard and smart port solutions that bring very specific benefits to our customers.”

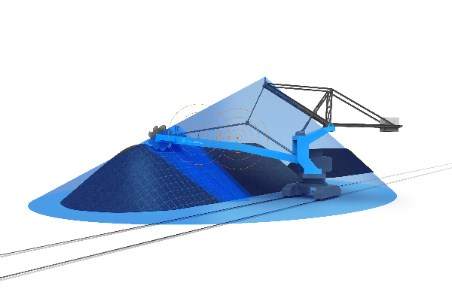

Autonomous Bucket Wheel Stacker Reclaimer (BWSR)

thyssenkrupp’s autonomous BWSR is designed to improve the use of dry bulk yards, optimising the material handling with a productivity gain of around 20% – when compared to conventional operations – and a 25% long-er equipment life, due to the stability of the operation provided by advanced automation. Consequently, the autonomous solution contributes to the reduction of CO2 emissions, because energy consumption is also enhanced.

“The algorithms we have developed work with parameters that make the equipment work at its highest performance, without moments of under-utilisation of the buckets – which lead to loss of productivity – or peaks of operation that cause stress and fatigue. We also avoid unnecessary production stops, which are generally an operational bottleneck”, explains Martin Krex, Global Product Manager Automation & Digitalization at thyssenkrupp Mining Technologies.

Hybrid Train Load Out Station (TLO)

For companies that operate with bulk materials, such as ores or coal, thyssenkrupp Mining Technologies has developed a Train Load Out Station (TLO) that uses artificial intelligence and machine learning techniques to improve loading accuracy. The system, called Hybrid TLO, combines volumetric and gravimetric type of operation and opens new options for fast and precise logistics. It allows loading ore at an average rate of 16 000 tph with great precision and manages to reduce the wagon loading time.

Read the article online at: https://www.drybulkmagazine.com/material-handling/08062021/thyssenkrupp-expands-portfolio-of-smart-stockyard-and-smart-port-solutions/

You might also like

Rio Tinto celebrates growth in Chinese market

Rio Tinto has celebrated shipping over 4 billion t of iron ore to China.